When you look up at a construction site and see a massive machine lifting heavy materials high into the air, you’re witnessing the power of a crane in action. These incredible machines have been shaping our world for centuries, evolving from simple wooden structures to the complex, high-tech marvels we see today.

Cranes are the unsung heroes of the construction industry and many others. They’re like the strong arms of a giant, reaching out to lift, move, and place materials that would be impossible for humans to handle alone. From building skyscrapers to loading cargo ships, cranes play a crucial role in shaping our modern world.

In this article, we’ll take a journey through the world of cranes, exploring 25 different types used across the globe. Whether you’re a construction professional, an engineering enthusiast, or simply curious about these mechanical marvels, you’ll find something interesting here. So, let’s get started and lift the lid on the fascinating world of cranes!

Table of Contents

- Tower Crane

- Mobile Crane

- Truck-Mounted Crane

- Crawler Crane

- Rubber-Tired Gantry (RTG) Crane

- Ship-to-Shore (STS) Crane

- Floating Crane

- Luffing Jib Crane

- Gantry Crane

- Overhead Crane (Bridge Crane)

- Heavy Lift Crane

- Telescopic Crane

- Rough Terrain Crane

- All-Terrain Crane

- Aerial Crane

- Carry Deck Crane

- Pedestal-Mounted Crane

- Barge Crane

- Stacker Crane

- Self-Erecting Crane

- Level Luffing Crane

- Hammerhead Crane

- Bulk Handling Crane

- Giant Cantilever Crane

- Vehicle-Mounted Crane

- Conclusion

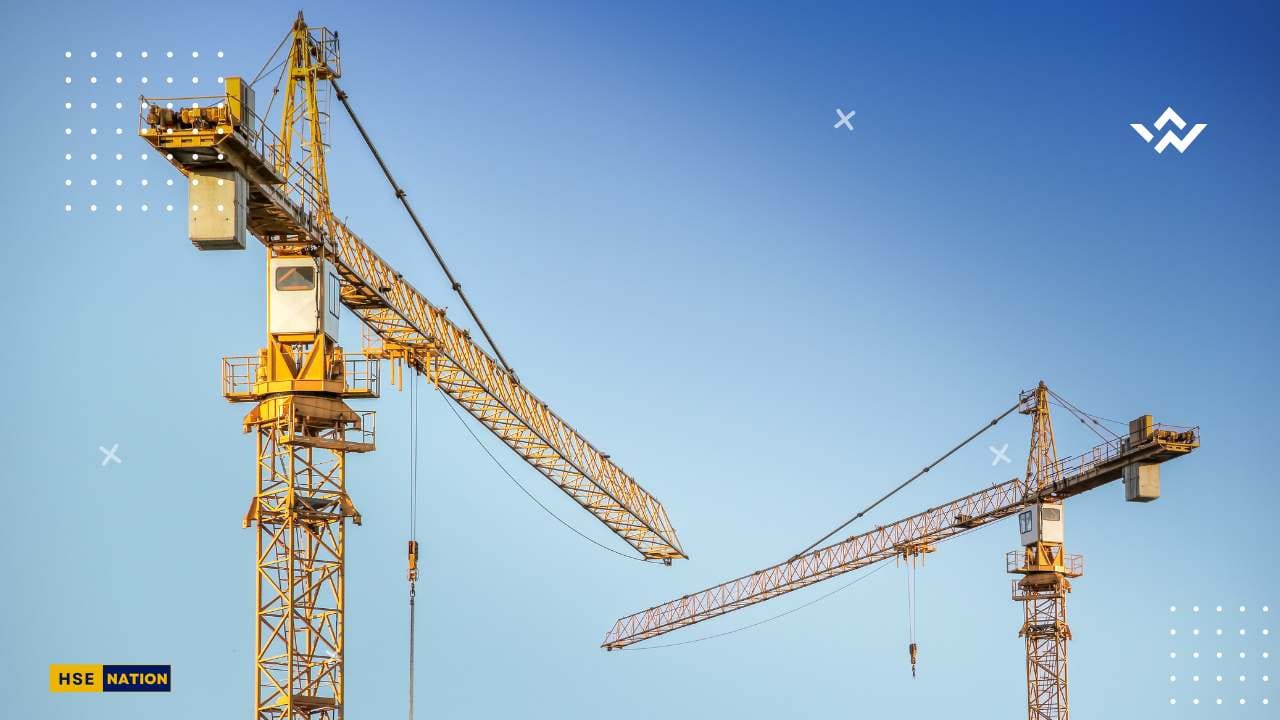

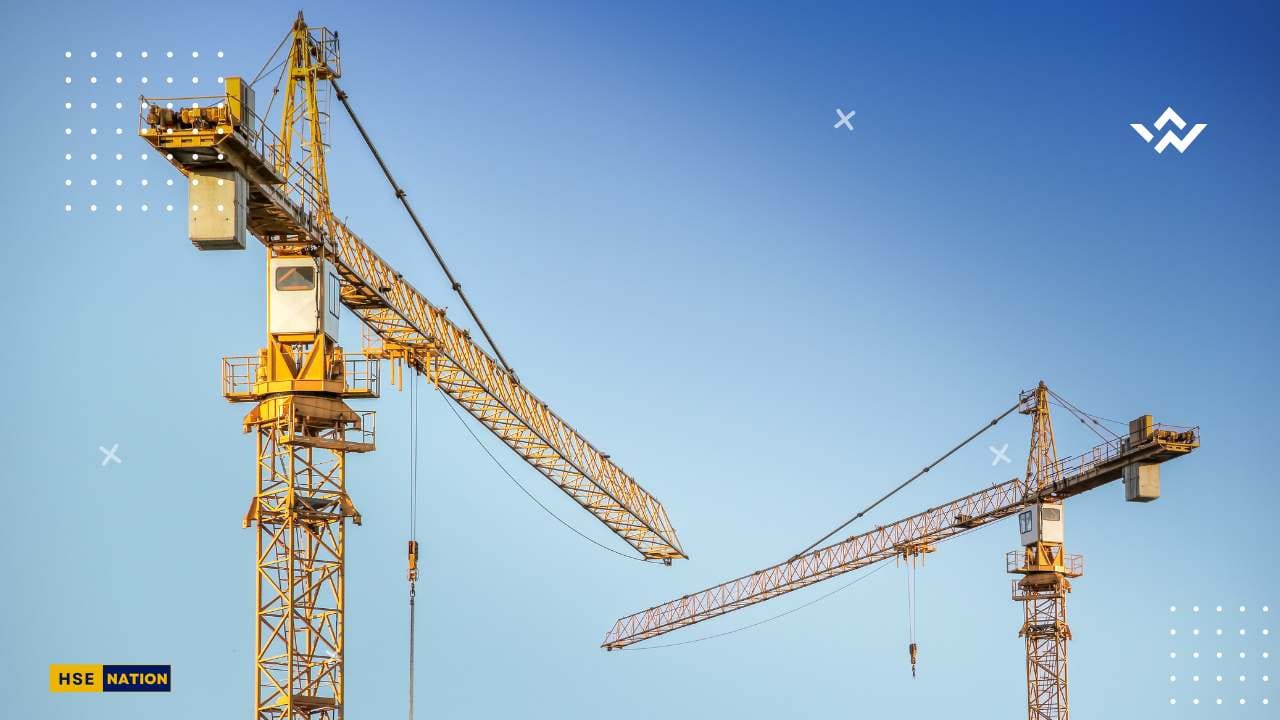

1. Tower Crane

1.1 Description and Features

Picture a tall, T-shaped structure dominating the skyline of a construction site – that’s a tower crane. These giants can reach heights of over 250 feet and lift loads of up to 20 tons. They’re the go-to choice for building skyscrapers and other tall structures.

1.2 Advantages and Limitations

Tower cranes are like having a super-strong, really tall friend on your construction site. They can reach high and lift heavy loads, making them perfect for high-rise construction. However, they’re not without challenges. Setting up a tower crane is a bit like assembling a giant Lego set – it takes time and careful planning. Plus, strong winds can be a real headache for operators, sometimes forcing work to stop for safety reasons.

2. Mobile Crane

2.1 Description and Features

Think of a mobile crane as the Swiss Army knife of the crane world. It’s versatile, easy to move around, and comes in handy in various situations. These cranes are mounted on wheels or tracks and have a telescopic boom that can extend to lift loads.

2.2 Advantages and Limitations

The beauty of mobile cranes lies in their flexibility. They can drive to a job site, do their work, and then move on to the next task. However, they’re not as mighty as their stationary cousins when it comes to lifting capacity. It’s a trade-off between mobility and power.

3. Truck-Mounted Crane

3.1 Description and Features

Imagine a regular truck with a crane attached to its back – that’s essentially what a truck-mounted crane is. These cranes are perfect for jobs that require quick setup and mobility. They’re commonly used for tasks like delivering building materials or setting up billboards.

3.2 Advantages and Limitations

The main advantage of truck-mounted cranes is their ability to hit the road. They can travel at highway speeds to reach job sites quickly. However, they’re not the best choice for very heavy loads or tall structures. Think of them as the sprinters of the crane world – fast and agile, but not built for marathon lifting sessions.

4. Crawler Crane

4.1 Description and Features

Crawler cranes are like the off-road vehicles of the crane world. They move on continuous tracks (like a tank) instead of wheels, which gives them excellent stability and the ability to navigate rough terrain. These cranes are often used in large construction projects or in areas with uneven ground.

4.2 Advantages and Limitations

The big advantage of crawler cranes is their stability. They can work on slopes and uneven surfaces where other cranes might topple over. However, they’re not exactly speed demons. Moving a crawler crane from one site to another is a slow process, often requiring special transportation.

5. Rubber-Tired Gantry (RTG) Crane

5.1 Description and Features

If you’ve ever seen a giant, bridge-like structure moving around a container port, you’ve probably spotted an RTG crane. These cranes run on rubber tires and are used to stack and move shipping containers. They’re like giant mechanical sorting machines for ports.

5.2 Advantages and Limitations

RTG cranes are great for organizing container yards efficiently. They can move around the port area, unlike fixed gantry cranes. However, they’re not as powerful as some other types of port cranes, which can limit their use for the heaviest containers.

6. Ship-to-Shore (STS) Crane

6.1 Description and Features

STS cranes are the workhorses of container ports. These massive structures look like giant arms reaching out over the water to load and unload container ships. They’re crucial for the efficient operation of modern ports.

6.2 Advantages and Limitations

The main advantage of STS cranes is their ability to handle large volumes of cargo quickly. They’re like efficient assembly lines for loading and unloading ships. However, operating these cranes can be challenging, especially when dealing with ship movements and bad weather.

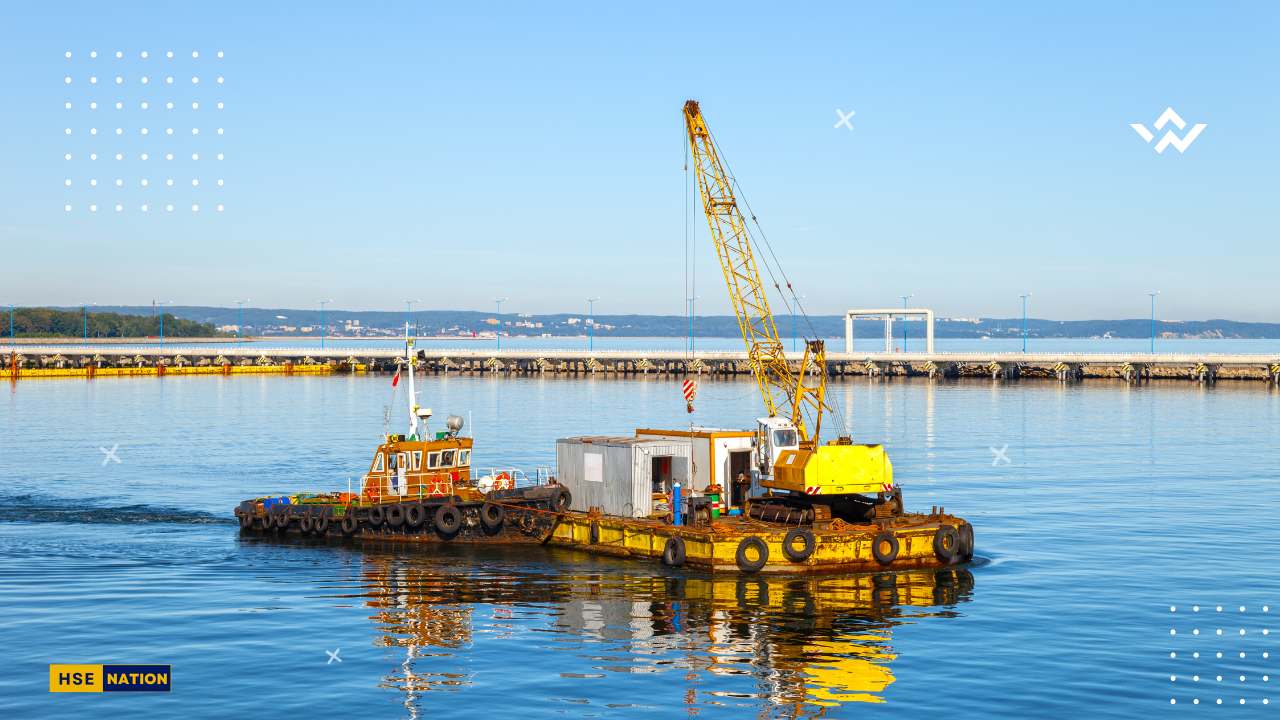

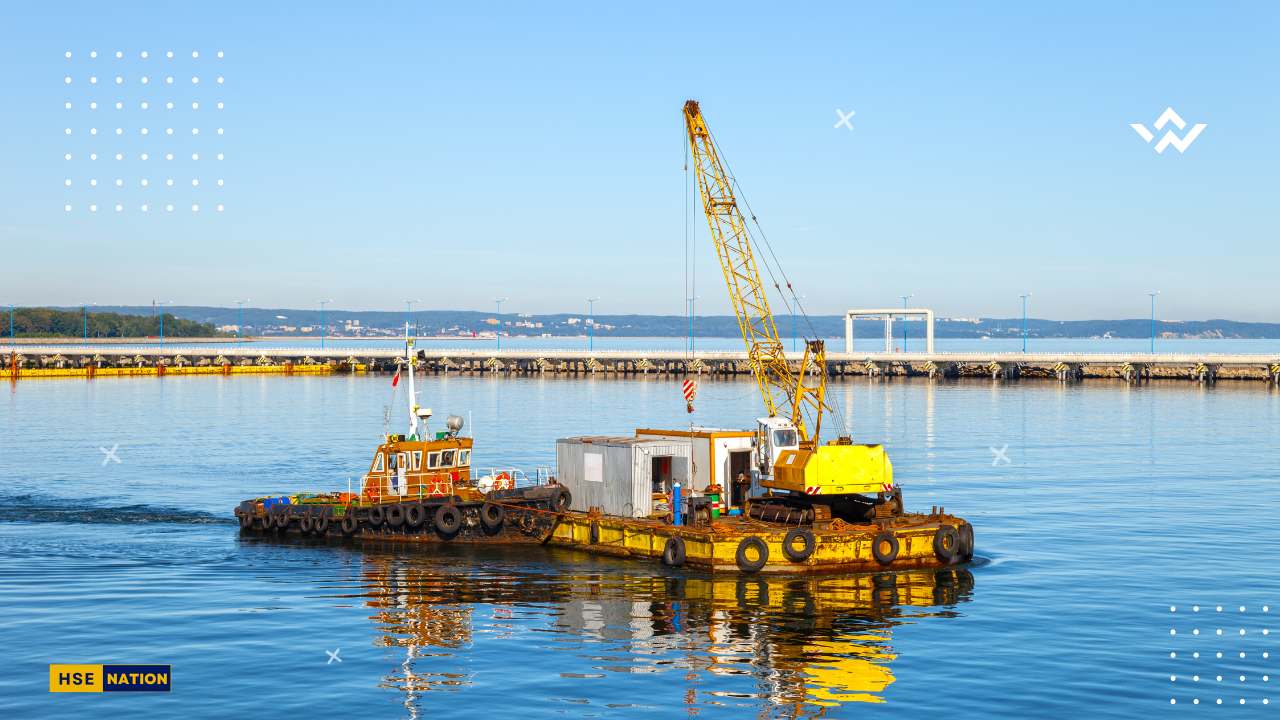

7. Floating Crane

7.1 Description and Features

Imagine a crane that can work on water – that’s a floating crane. These cranes are mounted on barges or special boats and are used for construction projects on water, like building bridges or offshore oil platforms.

7.2 Advantages and Limitations

Floating cranes are essential for maritime construction projects. They can reach places that land-based cranes can’t. However, they face unique challenges, like dealing with waves and currents. Operating a floating crane is a bit like trying to do precision work while standing on a waterbed!

8. Luffing Jib Crane

8.1 Description and Features

Luffing jib cranes are like the gymnasts of the crane world. They have a boom that can move up and down (luff) as well as swing from side to side. This flexibility makes them ideal for working in tight spaces, like crowded construction sites or shipyards.

8.2 Advantages and Limitations

The main advantage of luffing jib cranes is their ability to work in confined areas. They can maneuver around obstacles that would stump other cranes. However, they generally can’t lift as much as some other types of cranes.

9. Gantry Crane

9.1 Description and Features

Picture a giant, bridge-like structure that can move along tracks – that’s a gantry crane. These cranes are commonly used in shipyards, factories, and warehouses to move heavy loads across a specific area.

9.2 Advantages and Limitations

Gantry cranes excel at lifting very heavy loads and moving them precisely along a set path. They’re like having a super-strong assistant that can lift anything but only within a defined workspace. The downside is their lack of mobility beyond their tracks.

10. Overhead Crane (Bridge Crane)

10.1 Description and Features

Overhead cranes, also known as bridge cranes, are like gantry cranes but are typically found indoors. They run on elevated runways and are commonly used in factories and warehouses to move materials around.

10.2 Advantages and Limitations

The big advantage of overhead cranes is their ability to lift heavy loads without taking up floor space. They’re like having a strong helper that can reach any part of your workspace from above. However, installing these cranes can be complex and expensive.

11. Heavy Lift Crane

11.1 Description and Features

Heavy lift cranes are the superheroes of the crane world. These massive machines are designed to lift extremely heavy loads, often in specialized construction projects like building bridges or installing large industrial equipment.

Source: Sarens

11.2 Advantages and Limitations

The main advantage of heavy lift cranes is, unsurprisingly, their incredible lifting capacity. They can handle loads that would be impossible for other cranes. However, they’re not exactly nimble. Setting up a heavy lift crane is a major operation in itself, often taking days or even weeks.

12. Telescopic Crane

12.1 Description and Features

Telescopic cranes are like the extendable selfie sticks of the crane world. They have a boom that can extend to reach different heights, making them very versatile. You’ll often see these cranes used in construction, maintenance, and even in setting up outdoor events.

12.2 Advantages and Limitations

The big advantage of telescopic cranes is their adaptability. They can adjust their height to suit different tasks, making them very useful for varied work. However, they can become less stable when fully extended, especially in windy conditions.

13. Rough Terrain Crane

13.1 Description and Features

Rough terrain cranes are the off-road enthusiasts of the crane family. They’re designed to operate in unpaved areas and difficult terrain. With their large, rugged tires and four-wheel drive, they can go where other cranes fear to tread.

13.2 Advantages and Limitations

The main advantage of rough terrain cranes is their ability to work in challenging environments. They’re like the mountain goats of the crane world – sure-footed and adaptable. However, they’re not as fast or smooth on regular roads as some other mobile cranes.

14. All-Terrain Crane

14.1 Description and Features

All-terrain cranes are the jack-of-all-trades in the crane world. They combine the mobility of a truck-mounted crane with the off-road capabilities of a rough terrain crane. These versatile machines can handle a wide range of jobs in various environments.

14.2 Advantages and Limitations

The big advantage of all-terrain cranes is their flexibility. They can travel on highways, work on construction sites, and navigate rough terrain. However, they’re not as specialized as some other cranes, which means they might not be the best choice for very specific or extreme tasks.

15. Aerial Crane

15.1 Description and Features

Aerial cranes take lifting to new heights – literally. These are helicopters equipped with cables and winches to lift and transport loads. They’re used in remote areas or for tasks that require quick deployment.

15.2 Advantages and Limitations

The main advantage of aerial cranes is their ability to reach places that are inaccessible to ground-based cranes. They’re like the superheroes of the crane world, swooping in to save the day in hard-to-reach locations. However, they’re limited in how much they can lift compared to ground-based cranes, and their operation can be very expensive.

16. Carry Deck Crane

16.1 Description and Features

Carry deck cranes are like the compact cars of the crane world. They’re small, mobile, and can rotate 360 degrees. These cranes are perfect for indoor use or in tight spaces where larger cranes can’t operate.

16.2 Advantages and Limitations

The big advantage of carry deck cranes is their maneuverability in confined spaces. They can squeeze into areas that would be off-limits to larger cranes. However, their compact size means they can’t lift as much as their bigger cousins.

17. Pedestal-Mounted Crane

17.1 Description and Features

Pedestal-mounted cranes are like the watchmen of the crane world. They’re fixed in one spot, usually on a pedestal, and are commonly found in ports, on offshore platforms, or in industrial settings.

17.2 Advantages and Limitations

The main advantage of pedestal-mounted cranes is their stability and reliability. They’re always there when you need them, ready to lift. However, their fixed position means they can only work within a limited area.

18. Barge Crane

18.1 Description and Features

Barge cranes are like the seafaring cousins of land-based cranes. They’re mounted on floating platforms and are used for marine construction, salvage operations, and transshipment of goods.

18.2 Advantages and Limitations

The big advantage of barge cranes is their ability to work on water. They can handle tasks that would be impossible for land-based cranes. However, like all water-based operations, they’re at the mercy of weather conditions.

19. Stacker Crane

19.1 Description and Features

Stacker cranes are the librarians of the warehouse world. These automated systems are used to store and retrieve goods in high-bay warehouses. They move along aisles between storage racks, efficiently organizing inventory.

19.2 Advantages and Limitations

The main advantage of stacker cranes is their efficiency in handling inventory. They can work tirelessly, day and night, organizing and retrieving goods. However, they’re limited to specific warehouse layouts and can’t handle very heavy loads.

20. Self-Erecting Crane

20.1 Description and Features

Self-erecting cranes are like the pop-up tents of the crane world. They can be transported to a site and set themselves up with minimal external help. These cranes are ideal for short-term projects or sites with limited space.

Source: Potain

20.2 Advantages and Limitations

The big advantage of self-erecting cranes is their quick and easy setup. They’re perfect for jobs that don’t justify the time and expense of erecting a tower crane. However, they generally can’t lift as much or reach as high as larger cranes.

21. Level Luffing Crane

21.1 Description and Features

Level luffing cranes are like the precision instruments of the crane world. They can move loads horizontally without changing the height of the load. This makes them ideal for applications where maintaining a constant height is crucial, like loading ships.

21.2 Advantages and Limitations

The main advantage of level luffing cranes is their ability to move loads horizontally with great precision. However, they’re more complex to operate than some other types of cranes, which can make them challenging for inexperienced operators.

22. Hammerhead Crane

22.1 Description and Features

Hammerhead cranes are named for their distinctive T-shape, which resembles a hammer. These fixed cranes are often used in shipyards and heavy construction projects. They’re like the strongmen of the crane world, capable of lifting very heavy loads.

22.2 Advantages and Limitations

The big advantage of hammerhead cranes is their impressive lifting capacity. They can handle loads that would be too much for many other types of cranes. However, they’re not mobile and require significant time and effort to install.

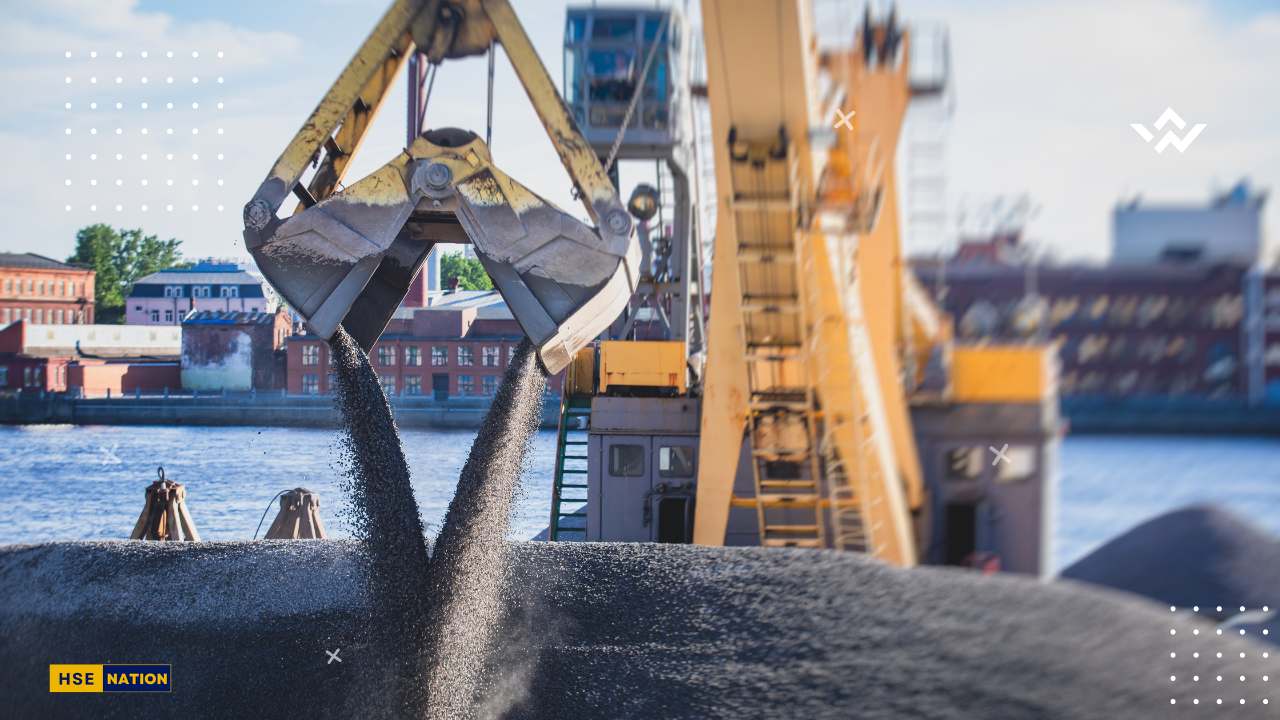

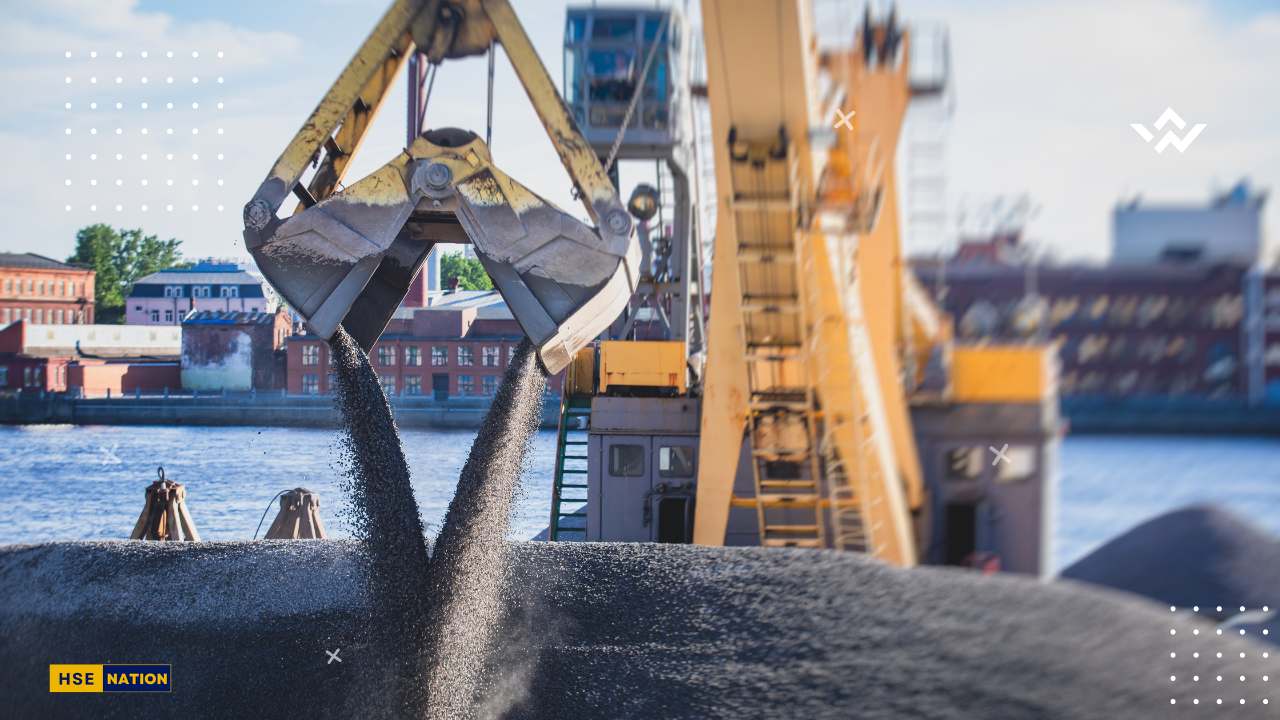

23. Bulk Handling Crane

23.1 Description and Features

Bulk handling cranes are the specialized tools of the crane world. They’re designed to handle loose materials like coal, ore, or grain. These cranes often use buckets or grabs to scoop up and move materials.

23.2 Advantages and Limitations

The main advantage of bulk handling cranes is their efficiency in moving large quantities of loose materials. They’re like giant scoops, able to move tons of material quickly. However, they’re not very versatile and are limited to specific types of cargo.

24. Giant Cantilever Crane

24.1 Description and Features

Giant cantilever cranes are the true titans of the crane world. These massive structures are used for extremely heavy lifts in large construction projects or shipyards. They’re like the elephants of the crane family – enormous and incredibly strong.

24.2 Advantages and Limitations

The big advantage of giant cantilever cranes is their ability to lift extremely heavy loads. They can handle weights that would be impossible for most other cranes. However, they require a lot of space and are very expensive to set up and operate.

25. Vehicle-Mounted Crane

25.1 Description and Features

Vehicle-mounted cranes are like the Swiss Army knives of the crane world. These are cranes mounted on standard vehicles, allowing for quick deployment and versatility. They’re commonly used for tasks like maintenance work or small construction jobs.

25.2 Advantages and Limitations

The main advantage of vehicle-mounted cranes is their mobility and quick setup. They can drive to a job site, perform a lift, and then move on to the next task quickly. However, they generally can’t lift as much as larger, specialized cranes.

Conclusion

As we’ve seen, the world of cranes is diverse and fascinating. From the towering giants that build our skyscrapers to the nimble machines that organize our warehouses, each type of crane has its own unique strengths and challenges.

Understanding these different types of cranes is crucial for anyone involved in construction, logistics, or industrial operations. Choosing the right crane for a job can mean the difference between a project that runs smoothly and one that faces constant setbacks.

But beyond their practical importance, cranes are a testament to human ingenuity. They’re a reminder of how we’ve learned to overcome our physical limitations, enabling us to build, move, and create on a scale that would have been unimaginable to our ancestors.

As technology continues to advance, we can expect to see even more innovative crane designs in the future. Who knows? The next generation of cranes might be able to build entire cities or help us construct habitats on other planets!

For now, though, let’s appreciate the incredible machines we have. The next time you see a crane at work, take a moment to marvel at the engineering and skill that goes into its operation. And remember, whether it’s a tiny carry deck crane or a massive ship-to-shore giant, each crane plays a vital role in shaping our world.

Stay safe, stay curious, and keep looking up – you never know what amazing feat of engineering you might spot in action!